Client

Parsley Energy is an independent oil and natural gas company focused on the acquisition, development, exploration and production of unconventional oil and natural gas reserves in the Permian Basin.

Problem

Leadership of the accounting, supply chain, and operations departments at Parsley wanted better visibility into operational-spend trends in order to identify cost-reduction opportunities and track supplier cost validation. Spend detail for their reporting was limited to the general ledger (GL) category, subcategory, and supplier levels. Performing invoice-level forensics required hours of effort and staff to pull specific invoices manually. To further complicate matters, suppliers of similar goods and services described their offerings in different ways. One drilling services provider might use “operating” to describe its services, while another might use the term “day rate” for the exact same service. These inconsistencies in line-item descriptions made consolidating and analyzing costs for product categories and services time-consuming and burdensome. After working internally to create a solution, Parsley engaged Stonebridge Consulting to analyze their current approach and to recommend a path forward.

Solution

Stonebridge worked closely with Parsley client sponsor Cecilia Camarillo, Senior Vice President of Accounting, and key stakeholder Andrew Scott, Director of Supply Chain Management, to define and refine the project’s parameters. Stonebridge consultants performed a spend-supplier analysis that included a detailed review of six months of invoices for drilling, completions, LOE, and water/facilities. They then conducted review sessions with invoice-data stakeholders—including representatives from accounting, supply chain, and operations—to address specific use cases and align recommendations. Throughout the project, Stonebridge reconvened with the various stakeholder groups to ensure project deliverables where precisely aligned with use cases and met end-user expectations. These steps led to the development and rollout of a spend-analysis solution built on three core components.

- Expanded Code Hierarchy. To maximize spend visibility, the Parsley stakeholder groups worked with Stonebridge to get a more granular view of spend by defining new spend-level coding levels below the GL category/subcategory level. The purchase category code (PCC) narrows the coding scope by defining and grouping cost categories across all spend categories. Item master (IM) further sharpens the focus through normalization of supplier line-item descriptions linked to specific goods and services. The entire hierarchy is retained in a structured database for reporting and analysis purposes.

- Auto-Coding. Parsley uses Enverus’ OpenInvoice electronic invoicing and PriceBook electronic catalog systems. The Stonebridge project team worked with suppliers to implement the new coding structure into new and existing PriceBooks, which enables the operator to validate spend at the supplier level while developing a database of enhanced spend data. Additionally, Stonebridge utilized OpenInvoice’s auto-coding capability, which eliminates manual coding, and significantly improves data quality for spend-analysis, well costs, and accrual reporting.

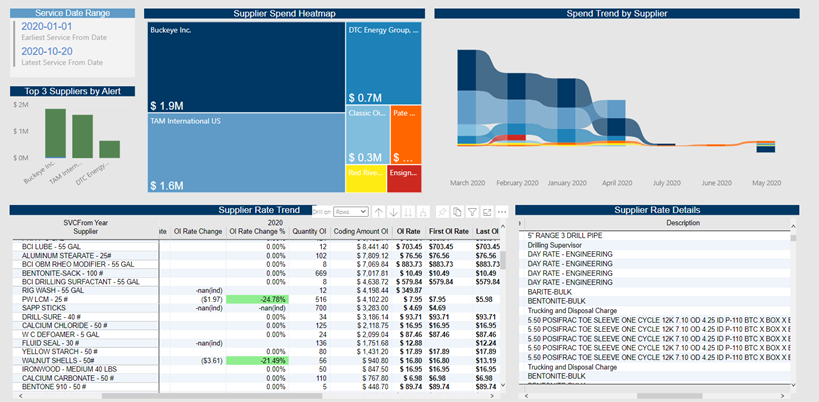

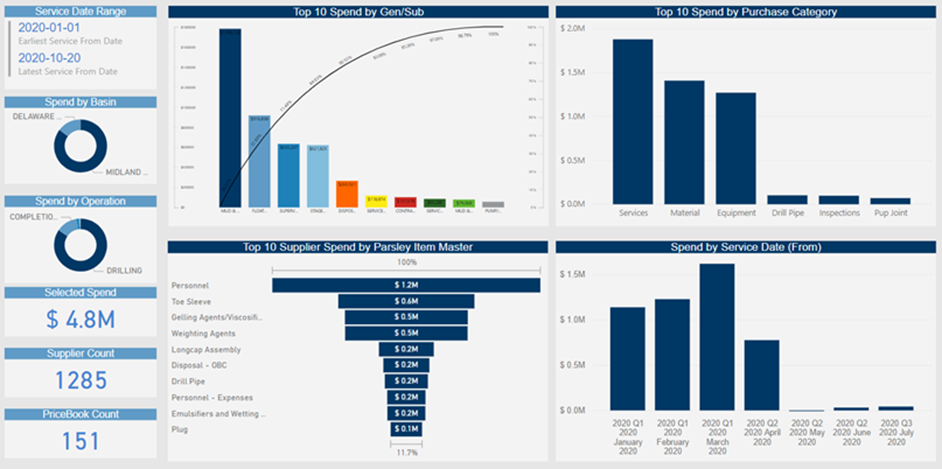

- Spend-Visibility Dashboard. Utilizing stakeholder feedback for data visualizations, Stonebridge utilized Power BI to create a supplier-spend dashboard with three views: spend visibility, spend visibility details, and price trends. The dashboard provides an efficient and effective way for Parsley users to access the enhanced spend data to identify opportunities for cost savings such as supplier consolidation, rate normalization, and compliance to negotiated rates. Global filtering enables users to maintain preferred views from dashboard to dashboard. Users can filter by location (basin, well, orientation), supplier, service date, and spend-code hierarchy (GL name, purchase category, item master, alert code, invoice status, AFE type, AFE number, etc.). The price trend dashboard provides Parsley a powerful tool to validate negotiated rates and enables quick visibility into price changes and trends over time.

Value

The spend-analysis solution provides sustainable business value to Parsley’s project sponsors and for all stakeholder groups. For accounting, the deeper spend-code structure provides the ability for cost management discipline, meeting internal audit requirements and enables accounting to perform cost analysis faster and more accurately. For supply chain, having enriched supplier-spend data at their fingertips through a visualization tool allows the supply chain team to function as a valued strategic resource, helping create competitive advantage and driving organizational excellence.

Quotable Quotes

Cecilia Camarillo

Senior Vice President of Accounting

Parsley Energy

“The Stonebridge team was able to assist Parsley with the spend-analysis project in multiple ways. First, they led the project management efforts which kept all stakeholders engaged while aiding the collective decision making process. Second, Stonebridge analyzed Parsley’s data and based on their fact-finding, they made recommendations as to the overall project goals. Lastly, Stonebridge provided numerous options and handled the development and look/feel of the actual Power BI dashboard. Working with Stonebridge was a win-win for Parsley on the spend-analysis project.”Andrew Scott

Director of Supply Chain Management

Parsley Energy

“Parsley is a small and nimble organization with a fairly new supply chain organization. When I joined Parsley, one of the first opportunities I saw was to standardize the taxonomy of the accounting codes in order to enable our team to do detailed spend analysis. For us to create this structure and undergo this business transformation, we needed to partner with someone with experience both from a supply chain and an accounting perspective. Stonebridge provided that for us and with their assistance we were able to fast-track the project and perform in depth spend analytics – it allowed us to identify opportunities significantly faster than we would have been able to otherwise.”Leo Oei

Managing Director, Supply Chain Management

Stonebridge Consulting

“Parsley needed a partner with deep operational and supply chain experience to formulate the coding structure. Our focus on stakeholder alignment added an extra layer of confidence in delivering a solution that met, and sometimes exceeded, user expectations. Additionally, our familiarity with Enverus’ application suite, as well as our in-house expertise in business intelligence and KPI dashboards, accelerated the project timeline and minimized costs. The result is an effective and simple spend-analysis solution that enables accurate well costs and provides immediate ROI.”

Contact us to find out how supply chain practices and processes can deliver bottom-line results for your organization.